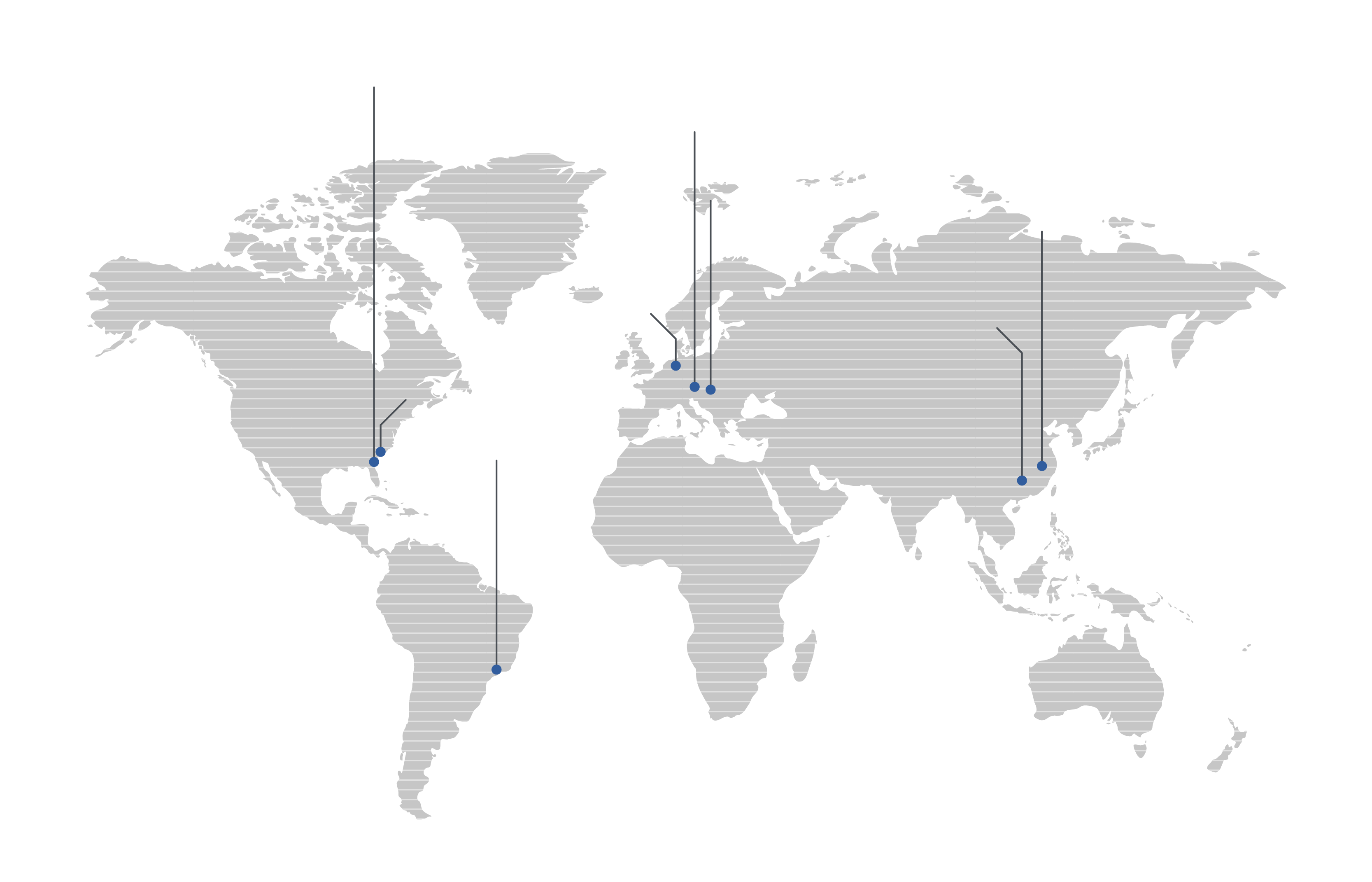

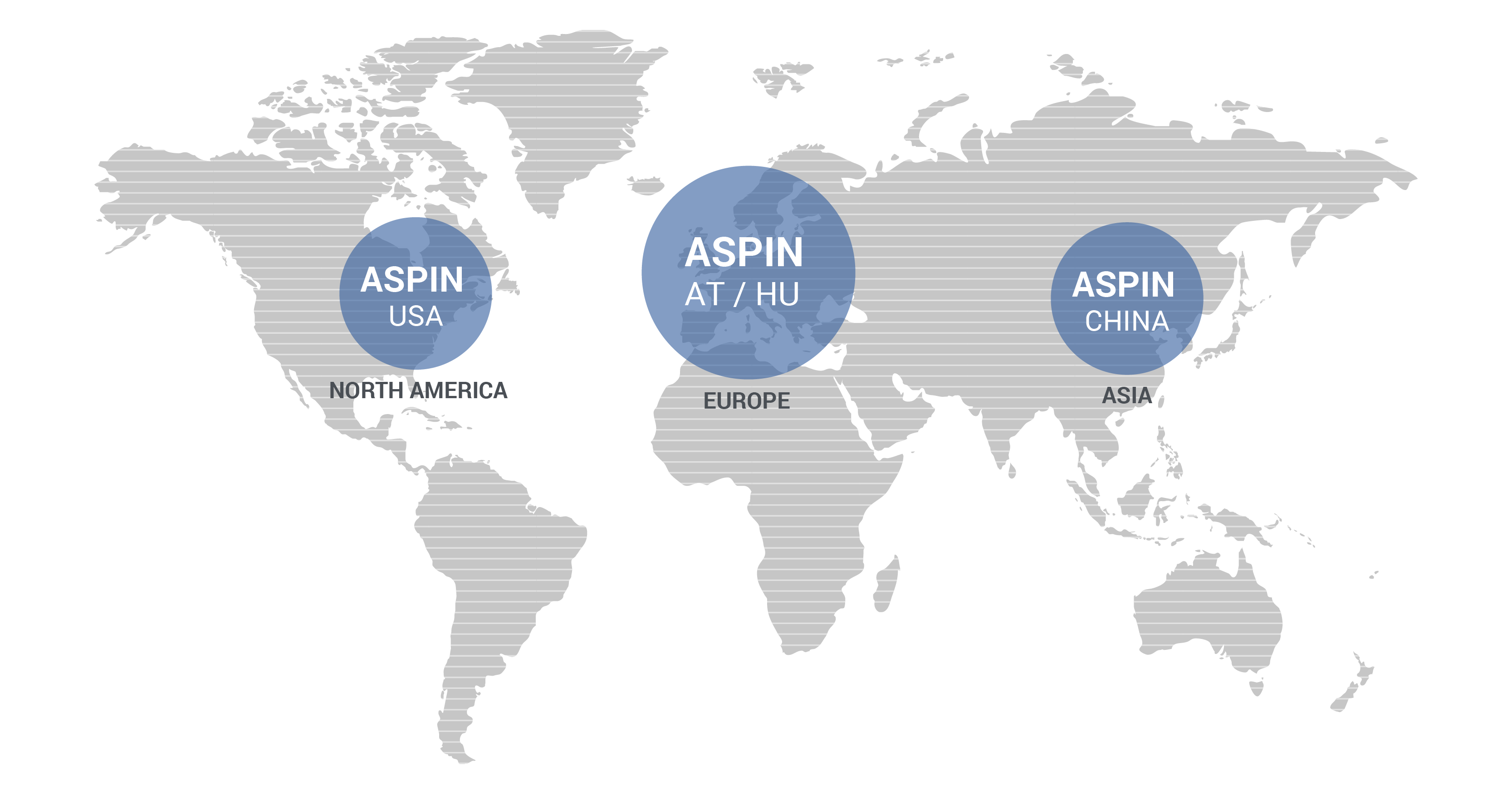

Reflecting the global progress in raising standards of product innovation, ASPIN provide solutions with special developed equipment that covers the electrical Motor Production sector, Slot wedge Production and development as well as Electrical Insulation Materials.

Major investment has led to further development of the company‘s product and service range. Our Products provide exceptional performance, with various configurations offering greater flexibility and costsaving benefits to both client and enduser.